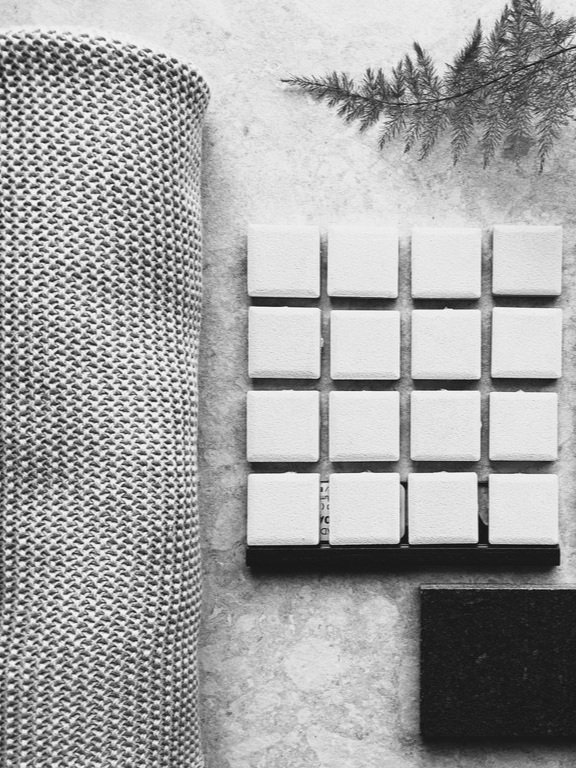

Material Moment: ENGINEERED HARDWOOD

Engineered hardwood

In the spaces we dwell, wood has long been the flooring material of choice. The texture, patterning and physical warmth of wood connects us to our senses and fulfills our human desire to tune into the natural world. In recent years, wood-look products such as laminate and luxury vinyl have risen in popularity and presence in interior spaces. It’s important to note, these products do not share all of the same characteristics of the real thing.

Differences in look, feel, acoustics and wearability between wood and wood-look are something your qualified interior designer will be ready to discuss when it comes to making those key material selections for your project.

Traditional, solid hardwood flooring is still produced and installed in a similar method as used a hundred years ago. Yet technology has undoubtedly impacted the industry and manufacturing processes of wood flooring, notably in the advancement of engineered products.

We had an opportunity to chat with Cheryl Gagnon from Fuzion Flooring about the properties of engineered hardwood and how it differs from its solid counterpart.

How does engineered hardwood differ from solid?

Solid hardwood flooring is made of solid wood throughout its total thickness. It is usually made of what we consider the domestic species such as oak, maple, birch, hickory or walnut. Its major advantage is that it can be refinished a number of times. Engineered wood looks very similar on the surface, but construction wise it’s made with a layer of hardwood that’s bonded to a substrate of either multiply or solid core construction and sometimes a HDF core.

For engineered wood, it will depend on the thickness of the hardwood top layer as to whether it can be refinished or not.

Are there benefits to choosing engineered flooring over solid?

With a more stable platform, engineered hardwood allows you to have wider & longer boards, giving you more variety in the finished aesthetic. It also displays less contraction and shrinkage than solid hardwood flooring. Furthermore, engineered hardwood can be installed on grade, above grade or below grade making it a very flexible option.

What are the variety of lengths and widths available?

Engineered hardwood is available in a variety of different widths from 3-1/2” and even up to 10-¼” and lengths as long as 86”.

How does the product selected impact its installation method?

Engineered hardwood flooring can be nailed/stapled, glued & floated. The type of installation is also determined by the substrate it’s being installed over. For example a concrete substrate (such as a basement) you would only be able to float it or glue it (with a full spread glue installation).

Thank you Cheryl for the insight on this material! You can find out more information on their product offering by visiting Fuzion Flooring’s website.