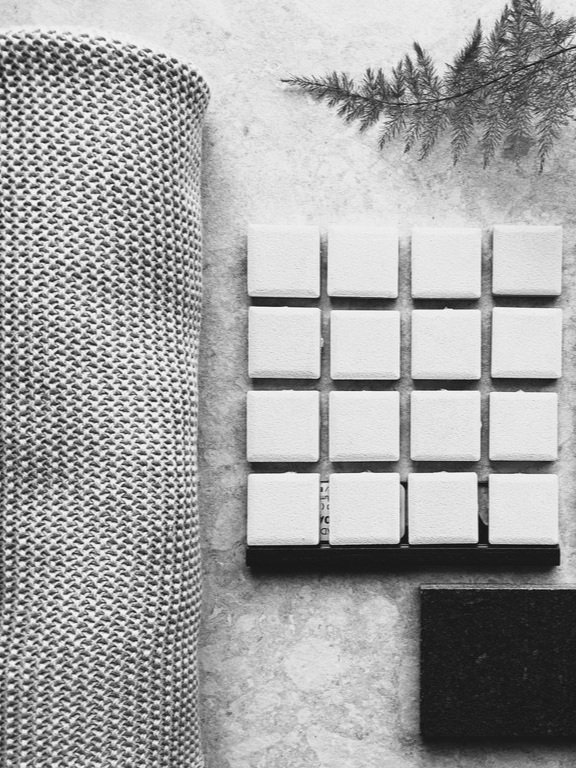

Material Moment: QUARTZITE

[ Quartzite ]

You may have heard of this surface material quickly gaining popularity in the design world. Quartz has been a favoured option for surfaces for some time and mimics a stone aesthetic without the maintenance required of natural stone (regular sealing due to its porosity). But quartzite is not quartz!

We had a chance to chat with Victoria Chagas from Ital-Stone Design who answered some questions for us about this surface material.

What is the difference between quartz and quartzite?

“Quartz is an engineered product made up of 93% quartz and the rest resin and pigments. Quartz is scratch, stain and heat resistant. Quartz is available in all colours from light to dark and simplistic to heavily veined and patterns. Overall, the ease of choosing quartz for the user is a desirable process, Designers and fabricators can simply show their clients samples or photos of the full slabs, setting expectations of what the product will look like installed!

“Quartzite is a 100% natural material. Patterns vary from block to block, slab to slab and corner to corner! It is important to choose quartzite based on large slab views, as the natural imperfections in slabs are sometimes undesirable. Quartzite must be sealed by the fabricator and monitored by the user. As the stone is porous, there is always a risk of etching, staining and scratching occurring. Quartzite has recently increased substantially in the Winnipeg market, which is exciting for fabricators and designers as working with natural materials is very exciting!”

What are the benefits of choosing quartzite as a surface material?

“The beauty of quartzite is unlike any other material. The patterns are extremely beautiful and have great depth. There are varieties of colours and patterns within the quartzite family, that cannot be compared to a granite, for example. Heat is not an issue with quartzite, so the user does not need to worry about damaging the stone, due its porous characteristics”.

What is the general maintenance?

“Although it is dense and hard, it is sometimes more susceptible to etching, staining and scratching. Some parts of quartzite slabs can be more porous than others, which means that the fabricator needs to take great care when sealing the product. Sealing should occur regularly. A good test is to leave water on the surface. If the water seeps into the pores of the stone, the surface requires more sealer. If the water just pools, you should be ok! Users should avoid leaving acidic substances and abrasive materials on the surface of quartzite or any natural material, for that matter”.

What slab thicknesses are available?

“Natural stones like quartzite tend to be stocked in 3cm (1 1/4") material, however, you can sometimes find it in 2cm (3/4"). It would be rare to find a quartzite thinner than this, due to natural stones being much more fragile during transport, fabrication and installation. All stones can be mitred to achieve a thicker look”.

Thank you Victoria for the great information on this material exciting material.

Ital-Stone Design are a local custom stone fabricator specializing in counter tops and custom surfaces.